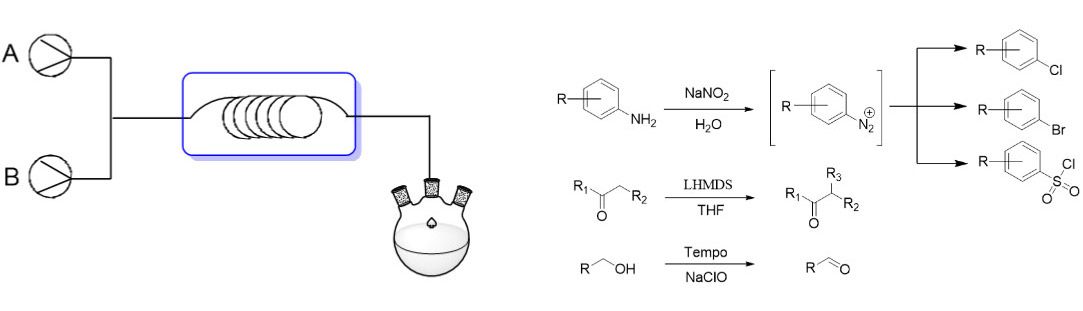

1. Capacity for the flow chemistry process optimization by the continuous flow reactor.

2. Capacity for the whole process optimization combining flow and batch chemistry.

Examples of developed flow chemistry processes

1. Designed Temperature: -15~200 °C. Designed Pressure: 0~5.5 MPa. Various types of reactions can be performed.

2. Flow Rate: 0.1~100 mL/min. Reactor Volume: 8.8 mL~88 mL. Gram to kilogram reactions can be performed.

3. The liquid-liquid, gas-liquid and other continuous flow reactions can be performed.

Charge Pumps

Continuous Flow Reactor

Continuous Flow Reactor

Gas-Liquid Separation

1. Appropriate equipment and capacity for manufacturing with flow chemistry and related batch chemistry.

2. Manufacturing experience of more than 1000 kg by flow chemistry process.

Tubular Reactor & Pump

Glass lined Reactor and Tube

Follow Us